Microprocessing is at the heart of many industries, creating components that are vital for modern technology. Laser technology not only reshapes microprocessing techniques it also propels precision engineering. Across diverse applications, from engraving to surface structuring, laser technology redefines the boundaries of micro-scale manufacturing across industries.

This technology presents a distinct advantage in microprocessing due to its versatility in working with various materials using a single tool. Unlike traditional manufacturing methods that often require multiple tools for different materials, lasers can effectively process a wide range of materials, including metals, plastics, ceramics, and even composites, with high precision and efficiency. Coupled with customization and efficiency, integrating lasers and, in particular, femtosecond lasers, offers a real competitive advantage.

Fundamental Applications of Laser Technology in Microprocessing

Laser technology plays a pivotal role in various aspects of microprocessing:

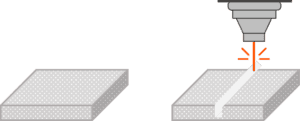

General Micro-Machining

& Engraving

The high manufacturing precision obtained with ultrashort pulse lasers on various materials allows for precise and elaborate micro components and precise engraving for traceability.

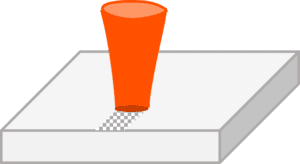

Surface Structuring

& Texturing

Laser-based surface treatments create unique textures (variations in surface smoothness, roughness, or patterns) and structures (physical shapes or configurations produced on the material such as microchannels, pillars, or grooves) at a micro-scale, modifying or enhancing micro-scale products’ surface functionalities and aesthetics.

Laser technology significantly impacts critical applications in microprocessing:

• Microelectronics and Micro Devices: In microelectronics manufacturing, lasers aid in precise micro-machining, allowing for the creation of micro-scale circuits and miniature components.

• Biomedical Micro Devices: Ultrashort pulse lasers play a crucial role in the medical field as well as the biomedical sector, rendering accessible the manufacture of micro-scale sensors, microfluidic chips and devices for biology analysis, microsurgical instruments, catheters, and micro-implants.

Laser technology transforms the field of microprocessing, driving precision engineering and advancements in large-scale manufacturing. Continued research and innovation in laser technology promise a future characterized by sophisticated micro-scale devices and pioneering technological applications.