Amplitude’s High Throughput Ultrafast Laser Processing with Femtosecond Bursts Drives New Opportunities

Thermal risks and ablation efficiency

It’s no secret: advanced technology has made today’s femtosecond lasers more than capable of delivering several hundred watts of output power. The problem is that the more power there is in pulses, the more potential thermal effects can degrade the processing quality. The objective now is how best to channel and distribute this power in order to improve the ablation process efficiency.

Amplitude has successfully met that challenge. The use of bursts has been identified as a key parameter in obtaining a high throughput, while also maintaining the quality and precision expected from a femtosecond laser.

Eric Audouard, Amplitude’s Laser Application Expert, explains the overview and outcome of this project.

Why Ablation Efficiency of Ultrafast Femtosecond Lasers Increases with Bursts

Low energy burst of pulses can reach the same ablation rate than high energy single pulse

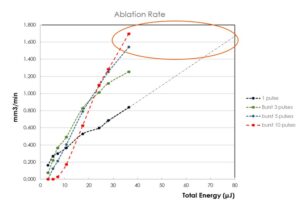

Ablation efficiency in many materials is usually higher when using low pulse energies, corresponding to moderate fluencies (energy density) on the sample. Therefore, if we use several pulses of total energy identical to a single pulse, we can improve this efficiency. With the ‘Burst Mode,’ instead of one single powerful pulse, the energy is distributed through several. Those are shot within a time interval which corresponds to the repetition rate of the oscillator (40 MHz).

This low ‘efficient’ fluence regime is then involved, even if we are using a high amount of energy in the total number of pulses comprised in the burst. Indeed, though Amplitude’s femtosecond lasers are already very precise, the use of this system enables our lasers to be much more efficient.

Moreover, thanks to the FemtoBurst™ function for specific applications, many possibilities for new applications can be opened for developing user-defined shapes (in both amplitude and time separation) of the burst.”

The Challenge of Utilizing High Throughput Lasers

The use of the Burst Mode provides a 10% to 30% increase in ablation efficiency, improving therefore throughput for our industrial clients. Yet, thermal effects are expected at a high repetition rate, as opposed to femtosecond single pulses which modify the matter with very low thermal effects. A new challenge therefore arises: a compromise between high throughput machining and high quality, as the latter is always expected from femtosecond lasers.

Applications and New Markets for Amplitude’s High Throughput Ultrafast Lasers

Amplitude’s High-Throughput Femtosecond lasers have always proven to be reliable products for our customers who micro-machine metals and semiconductors, especially when it comes to precision and efficiency.

Now with our system of bursts, we can keep on improving the productivity of our clients. Furthermore, our extensive research is also opening new avenues of implementation. We are indeed exploring the possibility of using the thermic effects of our Burst Mode for welding applications with femtosecond pulses, bringing them the ultrafast precision in the world of laser welding.