Impact of spectrum width on the field of view

When it comes to industrial femtosecond laser applications, every detail matters. From processing speed to precision and cost efficiency, choosing the right laser can define the success of your operation. At Amplitude, we are proud to deliver one of the broadest and most advanced ranges of high-power femtosecond lasers on the market, including the Satsuma X, Tangor, and Axis. These systems are engineered to provide unmatched performance in demanding applications such as texturing, cutting, and advanced material processing.

One critical factor influencing results is the spectrum width of femtosecond lasers, which directly affects both the field of view and the quality of the process. Amplitude lasers are designed to strike the perfect balance—short pulse durations combined with a narrow spectrum—giving users consistent performance across wide scanning fields.

Spectrum & femtosecond pulses

Femtosecond lasers deliver ultra-short pulses of light, with their duration (typically 400–500 fs in Amplitude lasers) closely tied to spectrum width. A fundamental principle applies: shorter pulse durations result in broader spectra. This relationship is a fundamental result of the Fourier Transform. While both parameters are important, no laser can simultaneously achieve the narrowest spectrum and the shortest pulse—there is always a trade-off.

- Narrow spectrum is advantageous, even mandatory, for some applications such as harmonic generation.

- Shorter pulses are crucial in other cases where energy transfer efficiency is key.

Amplitude bridges this trade-off with lasers that achieve pulse widths shorter than 500 fs AND spectrum widths narrower than 2.5 nm (IR range)—delivering both performance and versatility.

The Advantage of a Narrow Spectrum

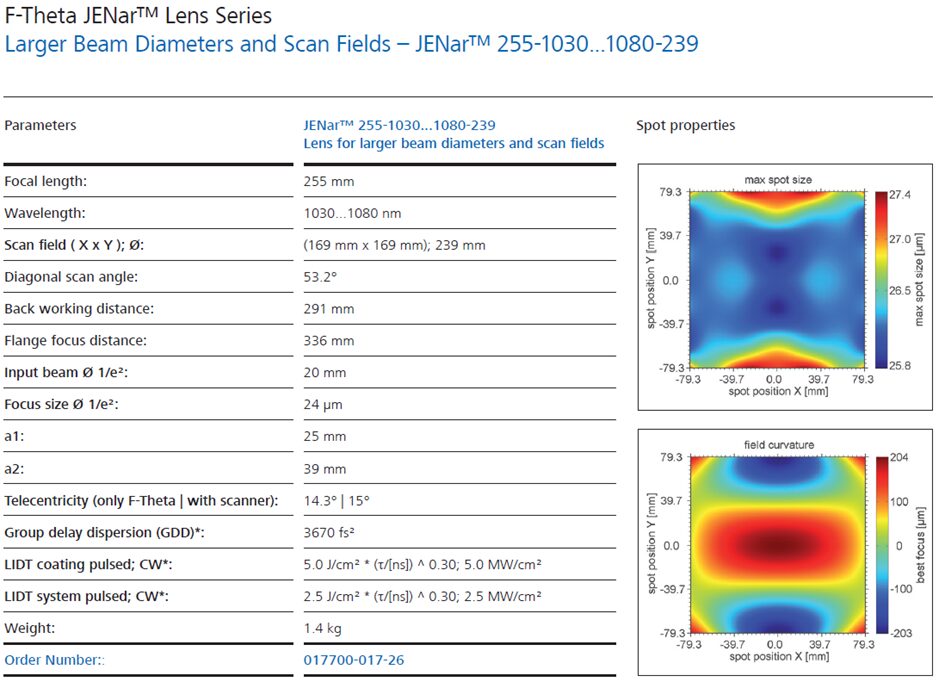

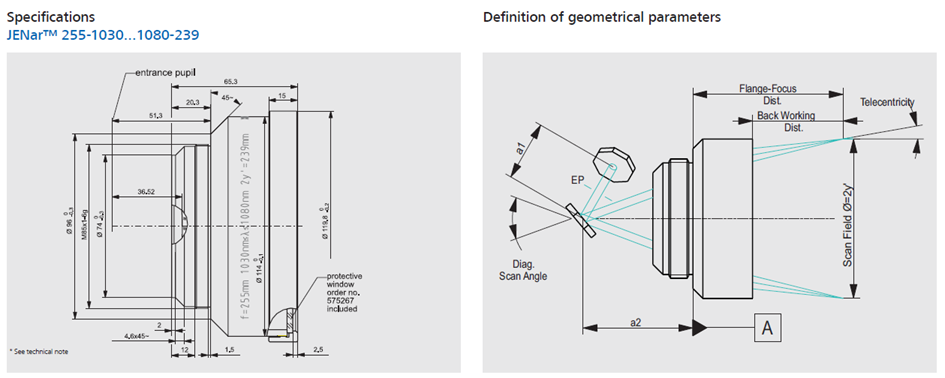

Using simulation data, we compared an Amplitude laser (spectrum width 2.5 nm, pulse width < 500 fs) with a competitor’s system (spectrum width 10 nm, pulse width < 350 fs). Both were modelled using a standard Jenar™ F-Theta scanning lens (f = 255 mm, Fig. 1), and the calculations were performed using Zeemax software.

The results are striking

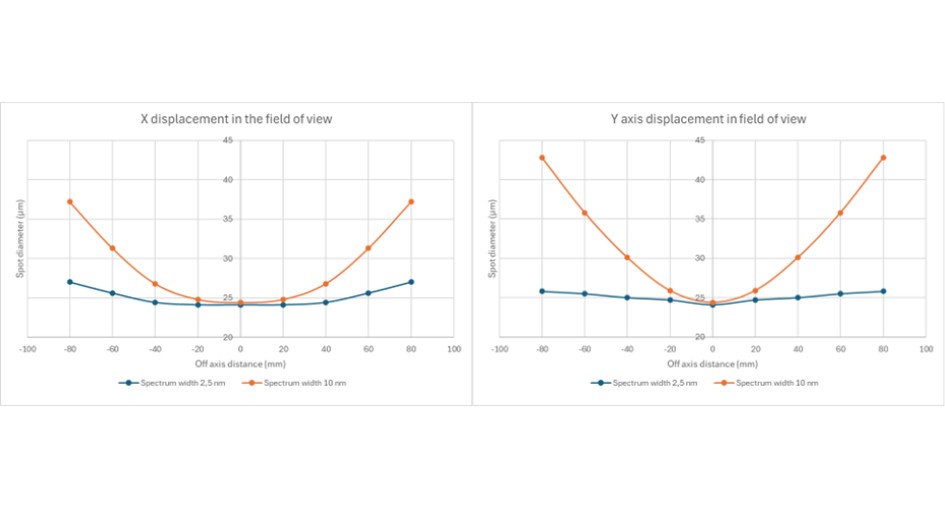

- Beam diameter stability : At the lens center, both lasers deliver similar spot sizes. But as the beam moves off-axis, the difference becomes clear. A broad spectrum beam grows up to 30% larger across X and 40% larger across Y at ±80 mm, while Amplitude’s narrow spectrum beam remains stable.

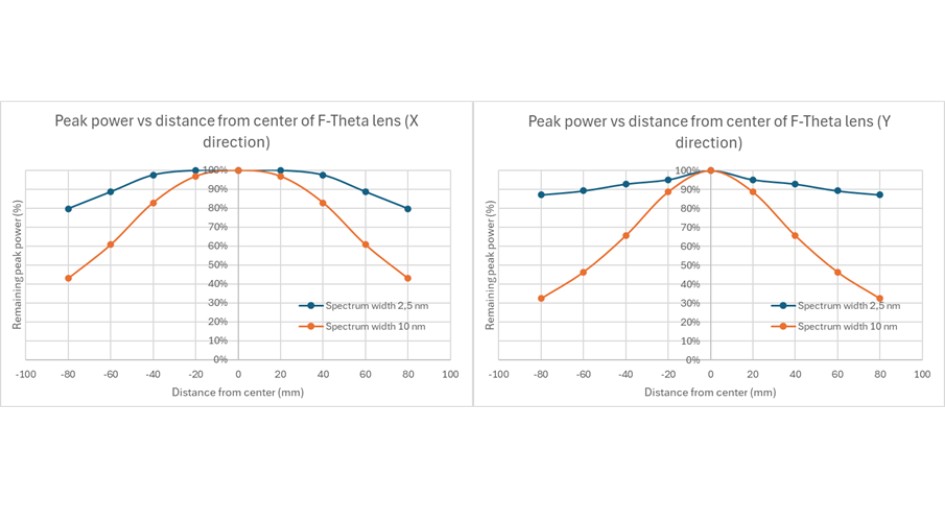

- Peak power retention : Peak power degrades rapidly with a broad spectrum—by 60–70% at ±80 mm from the lens center. In contrast, Amplitude lasers maintain nearly constant peak power across the entire field of view.

Fig 1 : Specifications of the Jenar™ F-Theta scanning lens (f = 255 mm) used for simulation.

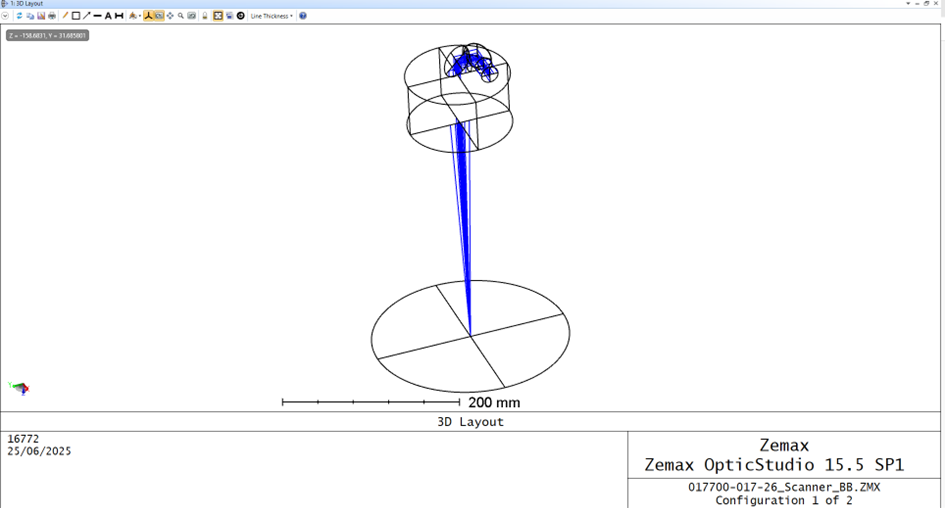

The computed 3D layout of the simulation model is shown in Fig. 2, where the scanner is represented by two mirrors displacing the beam along the X and Y axes. This setup illustrates how the beam is steered across the processing field.

Fig 2: 3D optical layout of the simulation model, showing scanner mirrors displacing the beam along X and Y axes.

We then calculated the peak power for both spectrum widths (2.5 nm and 10 nm) across the X and Y axes over the full scan field, as illustrated in Fig. 3. This comparison highlights how spectrum width impacts beam consistency across the entire field of view.

Fig 3: Displacement of the beam along X and Y up to the limit of the scan field

Focus plane

In most applications, the process is carried out in the focal plane of the F-Theta lens. For this model, the lens provides a working distance of 291 mm. Since the focal position can in principle be influenced by spectrum width, we calculated the working distance across the entire scan field for both spectra. The result was identical in both cases: 291.62 mm.

Beam diameter in the focal plane for both spectrum width

At the center of the F-Theta lens (X = Y = 0), there is no difference in spot size between a narrow or broad spectrum beam, as shown in Fig. 4. However, once the process requires moving off-axis by ±20 mm or more, the gap becomes clear: with a broad spectrum beam, the spot size increases significantly—up to 30% larger across X and 40% larger across Y at ±80 mm from the lens center. Over a 160 × 160 mm field, the broad spectrum beam is strongly affected by off-axis distance, while the narrow spectrum beam remains nearly constant. This demonstrates how Amplitude’s narrow spectrum design ensures stable precision across wide fields of view.

Fig 4: Beam diameter (µm) versus off-axis distance (mm) for narrow spectrum (2.5 nm) and broad spectrum (10 nm) beams.

The effect on peak power ( Energy/Spot surface ) is even more striking. As shown in Fig. 5, a broad spectrum beam suffers dramatic losses as soon as it moves away from the lens axis: at ±80 mm, the peak power drops by 60–70% compared to the center. In contrast, Amplitude’s narrow spectrum beam maintains nearly constant peak power across the same field. This stability translates directly into more reliable, higher-quality processing.

Fig 5: Peak power change versus distance from the F-Theta lens center for narrow spectrum (2.5 nm) and broad spectrum (10 nm) beams

In practice, a displacement of ±20 mm from the center may still be acceptable for broad spectrum lasers, as the impact on peak power is modest. But beyond that, spectrum width becomes a critical limitation. To achieve both process quality and large scan fields with a broad spectrum laser, users must often resort to costly solutions such as synchronizing galvos and stages to create an “infinite field.” By contrast, Amplitude’s narrow spectrum (< 2.5 nm) lasers, such as the Satsuma X and Tangor family, deliver quasi-constant spot size and peak power across ±80 mm, eliminating the need for such complex setups.

What This Means for Industrial Applications

For manufacturers, this translates into real, measurable benefits:

- Consistent processing across a wide field of view – no drop in quality as you move off-axis.

- Capability to process larger parts or multiple smaller parts simultaneously – without sacrificing peak power.

- Reduced need for expensive motion solutions – no need to combine galvos and stages to extend the scan field.

- Improved process reliability – fewer aberrations and higher repeatability.

In short, narrow spectrum lasers from Amplitude unlock higher efficiency and lower operational costs, especially for applications requiring extended scan fields.

Why Choose Amplitude?

With solutions like the Satsuma X and Tangor family, Amplitude provides high-power femtosecond lasers that combine short pulse durations with narrow spectrum widths—ensuring optimal performance for a wide range of industrial processes.

By choosing Amplitude, you are choosing:

- Stability and consistency across your entire processing field

- Flexibility to scale from small, detailed parts to larger components

- Proven laser technology trusted by industry leaders worldwide

Final Takeaway

A broad spectrum may seem attractive at first glance, but when it comes to processing quality, cost efficiency, and scalability, the advantages of Amplitude’s narrow spectrum, high-power femtosecond lasers are clear. By combining short pulse durations with a narrow spectrum width, systems like the Satsuma X and Tangor family deliver unmatched stability and performance across extended fields of view.

Summary

- Reduced aberration through the flat field lens – Narrow spectrum maintains a consistent spot size, whereas a broad-spectrum beam can see up to 60%+ enlargement at ±80 mm from the lens center.

- Extended field of view with minimal peak power loss – Narrow spectrum maintains power across the scan field, while broad-spectrum beams can experience up to 60–70% peak power degradation at ±80 mm off-axis.

- Process larger parts or multiple small parts simultaneously – Peak power remains stable across the full ±80 mm scan field.

- Avoid expensive galvo-stage combinations – Large scan fields can be processed without adding costly mechanical systems, even with high-quality results.