Glass Cutting Laser: Advanced Spatial and Temporal Shaping for Glass Cutting Application

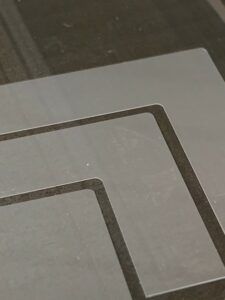

Fig. 1 Straight and Curved trajectories

Femtosecond lasers are known to be able to cut into nearly any materials. They are used to process semiconductors and other electronic components or custom pieces for various industries. Indeed, femtosecond laser micromachining is more precise and allows you to minimize the thermal effects on the matter, in order to produce higher quality pieces. PhD Konstantin Mishchik and his team at Amplitude, have worked on a new promising application for femtosecond lasers: glass cutting.

Femtosecond Laser Glass Cutting : How does it work ?

Ultrashort laser pulses combined with Bessel-like beams can be used to process glass. Bessel beams are thinner and longer than gaussian beams enabling simultaneous energy absorption of ultrashort pulses along whole glass thickness. The use of pulse bursts leads to more efficient laser absorption and leads to generation of cracks through the glass, from top to bottom. In Amplitude we developed a laser-based process which use the generation of cracks for glass cutting process when orientation of cracks is precisely controlled. That process can be used to cut either thin and ultrathin glass (<200 μm), thick glass (> 1 mm) or even several layers of glass or transparent materials with an easy separation, with low roughness and without chipping. Finally, the use of a femtosecond laser with Bessel-like beams is equally efficient to cut glass with straight or curved trajectories.

Cutting Thin Glass With Femtosecond Lasers Without Ablation

The key feature of the process, that the absorbed energy generates extended cracks far beyond the actual point of impact. This significantly accelerates the process time and increasing the efficiency of laser power use. For example, in the case of thin and ultrathin glasses, cuts at speed more than ~1m/s along the straight line and 100mm/s for curved parts can be achieved with only 10W of laser power.

It is also possible to cut thick glass or several layers of glass (>1 mm) in a single burst with this process. In that case, the experiments (with Tangor laser, manufactured by Amplitude, equipped with Femtoburst™️ function) revealed that the most efficient parameters is to produce one burst consisting of 4 to 6 pulses with a flat distribution of energy among them. The conical angle is set up as low as possible for processing up to 3mm-thick glass in a single pass.

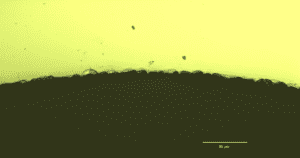

Fig. 2 Glass Cutting with Sandblasting

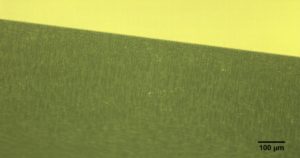

Fig. 3 Glass Cutting with a Femtosecond laser

How Does Femtosecond Lasers Have Improved Glass Cutting ?

The mechanical glass cutting techniques, like diamond wheel cutting or sandblasting or waterjet processes either not precise and/or tend to produce microcracks, dust and chips. The edges lack of regularity and therefore must be polished to reach an acceptable quality. A femtosecond laser, with the appropriate parameters, can execute clean cuts with very limited edge chips in one pass, even for thick glass, providing an alternative to the other glass cutting techniques.

To Whom Femtosecond Laser Glass Cutting is Addressed ?

This process mainly concerns mobile device displays manufacturers, that use thinner glass or multilayer glasses (ex. LCD) that often must be processed, with curved corners, contoured shapes and cut outs. Many of the mechanical or other laser methods cannot provide the level of precision and quality needed for this kind of products. Our technique can also be used to cut thicker resistant glass for the medical industry or even tempered glass for screen protection or the automobile industry for example.