Power Scaling and Pulse Shortening of Amplitude’s Ultrafast Lasers for Industrial and Scientific Applications Explained

Over the past 20 years, Amplitude has consistently increased the average power of its lasers. In 2001, our first laser was a 1W solid-state laser. As we approach a new year, our 2020 objective is to develop a 1000W laser. High throughput processing has opened new technologies and applications such as surface texturing and high-speed drilling. Power scaling and pulse shortening have also broadened the breadth of opportunities and applications. And at the forefront of scientific and industrial applications: high harmonics, EUV and soft X-rays.

Below, Clemens Hönninger, who heads up R&D at Amplitude, explains how power scaling and pulse shortening plays a vital role in our ever-evolving industry. Here’s his insight on this topic:

What is Power Scaling?

Image of a frontend laser from Amplitude seeding the 1 kW installation built by the University of Stuttgart for the HIPERDIAS project

“Power scaling consists of increasing the output power of a laser without spoiling other essential performance parameters such as the beam quality. The purpose of power scaling is to enhance productivity: machining becomes not only faster, but also more efficient with minimal damage to the material.

Amplitude has developed a hybrid fiber/solid-state amplifier in order to achieve a femtosecond laser that can deliver over 100W average power with high pulse energies and a flexible repetition rate.

A fiber oscillator, physically packed and protected, generates a pulse train of ultrashort femtosecond pulses at a high pulse repetition rate. To obtain high pulse energies at a given average power, the repetition rate must be reduced. This is achieved by a pulse picker placed between the oscillator and the amplifier chain. Then, the fiber amplifier section increases power and energy and maintains short pulses. When the light is confined in the 10 to 30 micrometer fiber, the energy density must be limited in order to avoid non-linear effects or damage to the fiber. Therefore, the energy is further amplified in a solid-state amplifier section, like an Yb-doped crystal.

Power Scaling and Pulse Shortening

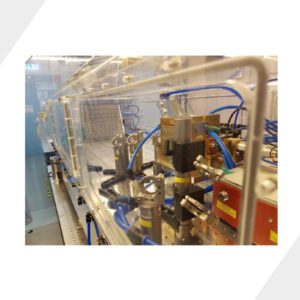

Installation of an Amplitude Multi pass cell and hollow core fiber

Industrial femtosecond lasers typically produce pulses with a duration of a few hundred femtoseconds in concert with the energy in the range of 1mJ peak powers of a few GW (with peak power being proportional to the ratio of pulse energy and pulse duration). Several applications, particularly high harmonics generation, EUV and soft X-rays, require significantly higher peak powers. Further energy scaling and pulse shortening also generate higher peak powers. Pulse shortening has become a popular way to do such ‘peak power conversions.’

Physically, pulse shortening consists of spectrally broadening the laser pulses’ spectrum via nonlinear processes encountered during the propagation of the laser pulse through a nonlinear medium. Then, these spectrally broadened pulses can be temporally compressed in a downstream compressor, typically consisting of a set of tailored chirped mirrors.

To shorten the pulses, we use the propagation through a hollow core fiber or a multi-pass cell in order to broaden the laser spectrum by non-linearity. The experiment was performed with a 100W-Tangor and pulse energies between 50 and 500μJ.

The results showed an excellent beam quality.”

Summary

The combination of power scaling with pulse shortening opens up many new applications evolving in both the scientific and industrial sectors, and, to some extent, blurring the division between these two markets. As we know, new applications can emerge and evolve rapidly. As a leading laser manufacturer, Amplitude will continue to develop lasers with shorter and shorter pulse durations to meet these escalating needs.