Femtoburst®

This optional function available on Tangor 100, Satsuma, Satsuma X and Tangor 300 augments precision and addresses the inherent challenges of natural burst decline due to elevated gain on initial pulses.

In this study, we look closely at how Femtoburst® works, how it fits with femtosecond lasers, and how it improves precision in different uses.

Femtoburst® is a technical solution meticulously engineered to redefine burst shaping. Its primary purpose is to enable users to exert fine-tuned control over burst output, a crucial factor in applications reliant on precise energy distribution and timing.

When left uncontrolled, a burst’s energy weakens because of stronger initial pulses. This can lead to non-optimal outcomes, especially when precise timing and energy distribution are critical.

The Spectrum of Shaping: Customizing Burst Characteristics

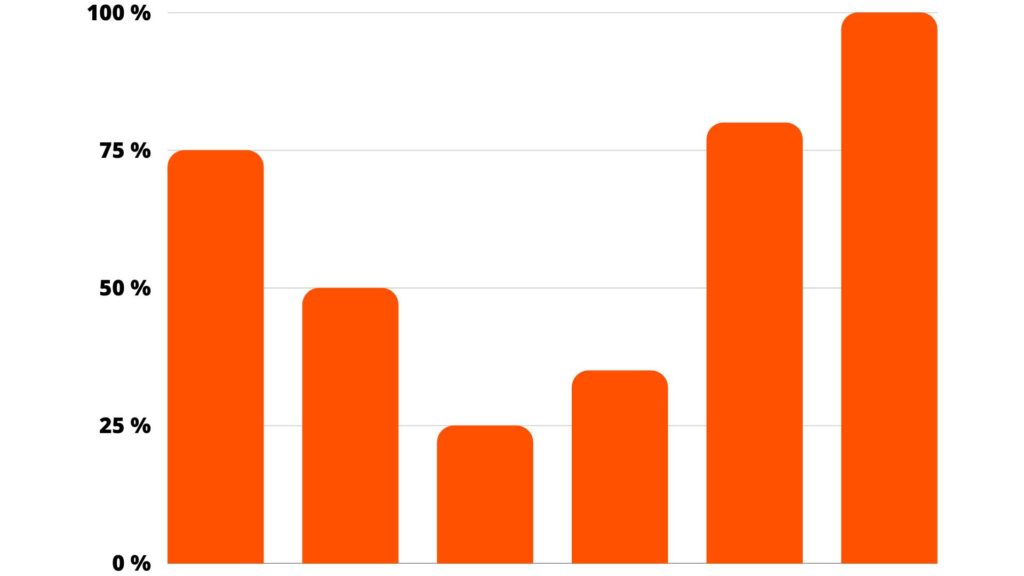

The power of Femtoburst® lies in its versatility, offering a spectrum of shaping possibilities. Imagine a decreasing burst, where each successive pulse carries slightly reduced energy, ensuring a gradual and controlled energy distribution. This contrasts with a flat burst, where each pulse maintains consistent energy, which is ideal for applications demanding uniform energy delivery. Alternatively, consider an increasing burst, where each pulse’s energy escalates, aligning with applications requiring energy augmentation. Femtoburst® is not just a function; it’s a technical toolkit enabling users to sculpt burst energy profiles precisely.

Applications Across Industries: Unveiling Practical Implications

Incorporating Femtoburst® within femtosecond lasers holds immense potential across various applications, enhancing precision and expanding possibilities. Some notable applications where Femtoburst® can be valuable include:

- Medical Procedures and Surgery: Precise energy distribution is paramount in laser-based medical procedures and surgeries. Femtoburst® can ensure accurate tissue ablation, enhancing the safety and efficacy of techniques like laser eye surgeries (LASIK), skin resurfacing, and even minimally invasive procedures like vascular treatments.

- Material Processing and Micromachining: Enabling intricate surface structuring, micro-drilling, and cutting with exceptional accuracy, vital in electronics and precision manufacturing.

- Scientific Research: Supporting ultrafast laser experiments, aiding pump-probe techniques, high-field physics, and laser-induced breakdown spectroscopy with accurate energy synchronization.

- Optical Imaging and Microscopy: In microscopy techniques like two-photon microscopy, precise energy distribution within bursts can improve imaging quality and reduce phototoxicity in biological samples. This is particularly relevant in neuroscience and cellular imaging.

- Precision Manufacturing: Industries like aerospace and automotive benefit from Femtoburst®-enabled femtosecond lasers for applications such as precision cutting, drilling, and texturing of various materials. The controlled energy distribution ensures high-quality and consistent results.

- Materials Research: Supporting thin film removal, surface modification, and controlled material ablation for material properties analysis.

- Photovoltaics: Precision patterning of solar cells for improved efficiency in solar energy harvesting.

- Microfabrication: Femtoburst® technology aids in fabricating intricate microstructures on materials like glass, polymers, and metals, which find applications in microfluidics, lab-on-a-chip devices, and more.

- Ultrafast Spectroscopy: Enabling detailed exploration of molecular and atomic properties through precise excitation energy control.

These applications merely scratch the surface of Femtoburst®’s potential. Its technical precision and ability to reshape burst output can elevate accuracy and results across many industries and research fields, where femtosecond lasers play a pivotal role.