Medical components such as implants and surgical tools require perfected manufacturing processes. The slightest alteration of the surface, the dimensions or the form may have a significant impact on their performance.

For these sophisticated and demanding applications, ultrafast lasers (femtosecond or picosecond) offer unique advantages: they can work on any type of material (ceramic, glass, polymer, metals) without emitting heat, and with both remarkable precision and exceptional quality. They are of a higher average strength and can therefore increase industrial productivity and accuracy.

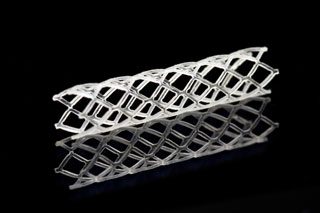

Among the typical applications, we can cite the production of new generation bio-absorbable stents, catheter treatment or texturing the surfaces of biocompatible implants. New applications are currently under active development, notably in the area of nano-technologies and manufacture of advanced additives.

Amplitude proposes a complete range of ultrafast lasers, of industrial reliability and perfectly adapted to these advanced applications. Feasibility studies or process development can be produced in partnership with our applications laboratory. Biocompatible materials are rare and must be manufactured on a very small scale in order to be injected. The nature of the material used is of paramount importance and must not be changed in any way. Absorbed by the body, these materials are fragile and poorly allow the interaction with certain lasers.

Our lasers solve this problem. With their extremely high repetition rates, our lasers prevent any change in the integrity of the biomaterial, such as corrosion resistance, making femtosecond technology the best option to use. Operating at this precision height, Amplitude-femtosecond lasers are the most in tune with the expectations of our customers manufacturing medical devices.