25W Ultraviolet Femtosecond GHz Burst Laser

Recently, Amplitude developed a GHz burst laser system capable of producing UV light, in order the improve micro-machining outputs. We interviewed the team of engineers working on the project to know a little more about it. Guillaume BONAMIS, Jorge SANABRIA and Eric AUDOUARD were kind enough to answer our questions.

What is a GHz machining ? What is its utility ?

GHz machining is the generation of burst of several impulses, instead of a single pulse. Indeed, to make it simple, rather than hitting once very hard on the material, we use a series of a hundred, very fast, but lighter impulses. In this process, the pulses are shot within a very short time interval, in the range of a nanosecond. The recent results showed that the use of those bursts for micromachining allows a more efficient ablation process than other laser-matter interactions ; while preserving the machining qualities expected from a femtosecond laser regular use.

If you wish to know more about GHz, please consult our article on the subject.

What are green and ultraviolet wavelengths ?

The infra-red light is the fundamental wavelength (1030 nm) for Amplitude lasers (Yb-based oscillators and amplifiers). When we double or triple the light frequency (dividing therefore the wavelength by 2 or 3) using a nonlinear conversion process, we can obtain green (510 nm) or ultraviolet (343 nm). The operation is done with the infra-red light passing through nonlinear crystals made of a specific material and carved a certain way to get the desired frequency. It is also possible to quadruple the frequency to get a more profound ultraviolet, also called “Deep UV”, with a wavelength reaching 257 nm.

At Amplitude, we are currently working to get high conversion rates. Because when the wavelength goes from 1030nm to 510nm, for example, we lose around 50% of the energy, and around 80% for the UV wavelength. The purpose is to improve the efficiency while preserving the quality of the beam. In the case of the GHz laser, the issue is that the energies by pulses are very low. The lower the intensity is, the harder it is to convert the wavelength.

Why are those wavelengths used for ?

There is a link between the wavelength and the diffraction limit. The lower the wavelength is, the more we can focus the beam. Therefore, the beam is more precise. It can be used in micromachining to get more efficient and accurate cuts.

Likewise, each material is going to absorb the wavelength differently. By dividing the infrared wavelength frequency, we lose average power, but the photon’s energy is more important. So when you use a material that reacts to photon’s energy, the UV allows a treatment of the matter that would not be possible with infrared, even with four times more average power. UV is well suited for polymers, plastics or organic materials. With fs pulse and UV, the best precision (lowest size of spots but also of thermal effects around the spots) is reached for laser processing.

How do you produce green or UV ?

Usually, we add behind our lasers, at the exit end, a conversion module to produce a green or ultraviolet wavelengths. But we did integrate the module directly into some systems to produce green. For example, the Satsuma is equipped with a nonlinear crystal and dichroic mirrors. When the beam passes through the crystal, it produces a green wavelength, but the infrared is still there. We use the mirrors to separate them from each other. The mirrors are going to reflect the green and let the infrared pass through, in order to get a green light only. Thisshould be integrated to our future lasers design (for green and UV outputs).

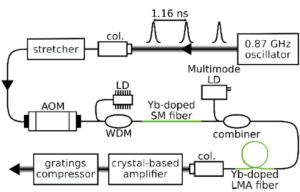

What manipulation did you do to produce UV with a GHz burst laser ?

What manipulation did you do to produce UV with a GHz burst laser ?

We use one of Amplitude’s existing standard conversion module. A first nonlinear crystal produces green light from the infrared light delivered by the Tangor and a second one generates UV light by the combination of green and remaining infrared. The challenge with a GHz burst laser is the lower energy per pulse available than for MHz single pulse laser, for the same 100 W of average power available (around 100 times lower, considering the number of pulses per burst). So we had to adjust the infrared beam size at the module’s entry to get the right intensity and be able to process the nonlinear conversion.

What did your observe when you processed the experiment ?

The goal was to get a decent output, and the results of the experiment turned out to be quite satisfactory. 25W UV was obtained at the laser exit. Therefore, we got a 25% output with a high cadence From our knowledge, nobody got this results before, so this is an interesting step to pursue our research.

What’s next ?

Logically, the goal now is to explore the applications of this technology. The idea is to test a source for material processing of extreme precision and better throughput. From an industrial point of view, we are going to test and perfect the system to make sure it can become an industrial product, that is robust, reliable and lasting. We are probably going to try to improve its durability and optimize its size.